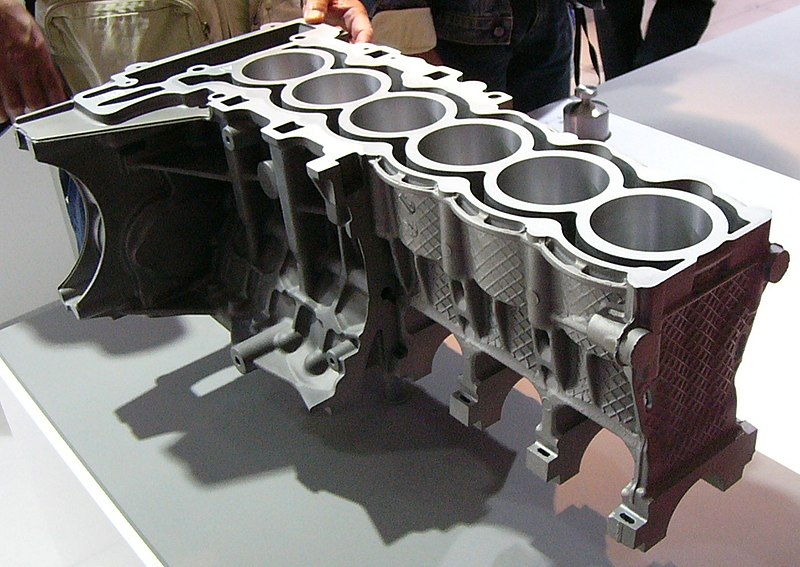

The core of diecasting is the mold known as a die. It carefully crafted out of solid steel, which is hardened to resist the extreme conditions of diecasting. The layout of the die is vital, since it has to accommodate the melting metal's flow and hardening while keeping tight tolerances in order to guarantee precision. In the process of diecasting that involves the use of metals, such as aluminum, zinc as well as copper are heated until they become molten. This molten metal is then put into the die cavity under pressure that is high, filling each and every inch of the mold. Rapid cooling and solidification of the metal result in pieces that display excellent dimensional accuracy and a smooth surface finish, often eliminating the need for additional processing or finishing.

One of the biggest advantages of casting dies is its effectiveness in mass production. After the dies have been fabricated and shaped, they are able to make thousands of similar parts that are identical with little variation. The high degree of repeatability is necessary for all industries where large numbers of standardized components. Furthermore, diecasting is recognized for its high efficiency of materials. Diecasting produces minimal scrap, because any excess metal can be reused and recycled for subsequent casting cycles. This reduces not just material costs but also supports environmentally sustainable practices in manufacturing, by minimizing production waste while also conserving resources. A combination of production speed, precision, and material efficiency makes diecasting an appealing option in the quest to maximize their processes for production.

Diecasting also excels in producing parts with superior mechanical characteristics. The rapid cooling of the liquid metal that is formed during the process of casting results in an extremely fine-grain design, which increases the durability and strength of the final product. Dies makes diecast parts ideal for use in applications that demand superior performance and durability. As an example, in automotive manufacturing Diecast components are utilized for transmissions, engines, and structural elements. their strength-to-weight ratio is critical for safety and vehicle efficiency. Also, in the aerospace industry, diecast components contribute to the development of lightweight yet strong structures, crucial for optimizing fuel efficiency and performance. To generate more information please try this web-site

Diecasting's materials are crucial in determining the properties and performance of the final product. Aluminum is one of the most widely used components because of its superior strength-to-weight ratio, resistance to corrosion, as well as its excellent electrical and thermal conductivity. Zinc alloys are also very popular for their quality, durability, and the ability to produce components with fine specifics. Magnesium alloys offer the benefit of being the lightest structural metal. This makes them the ideal choice for any application in which weight reduction is essential. Copper alloys are more rare, are employed due to their high electrical conductivity as well as their resistance to corrosion. The material selection depends on the particular requirements of the project, which includes physical properties, environment conditions and price factors.

Diecasting is a critical manufacturing process that allows for the production of high-precision, premium metal components for many industries. Its capability to make complicated shapes, with precise tolerances and smooth finish is essential for projects which require precise details as well as consistent quality. The efficiency and cost-effectiveness of diecasting further enhance its appeal and support mass production while maintaining the highest quality. As technology advances and the need for reliable robust, lightweight and long-lasting components expands, diecasting will continue to be a key component in modern manufacturing. This will lead to improvement and quality in production.